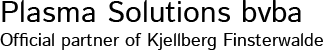

Kjellberg produces mechanised plasma technology for cutting various ferrous and non-ferrous metals. Q, HiFocus, Smart Focus, CutFire or PA-S … there’s a plasma power source for any cutting job.

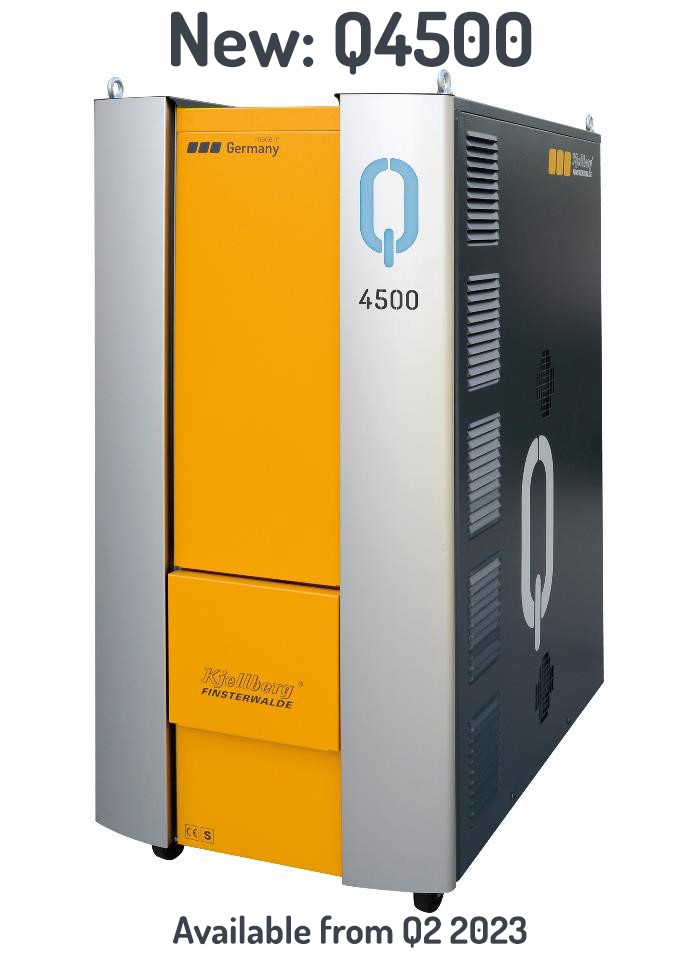

With its latest generation of plasma power sources – Q – Kjellberg is fully committed to developing the smart factory and e-services as part of industry’s digital transformation (Industry 4.0).

These revolutionary plasma power sources achieve operational communication through EtherCAT. Thanks to the seamless connection with the guiding system and all other components in the production process, this delivers the best possible cutting results.

Q helps to optimise Kjellberg Contour Cut and Silent Cut technology even further. The power source uses 100% digitally controlled inverter modules for optimal cutting and marking current control – resulting in the highest cutting and marking quality and extending the lifetime of the torch consumables.

All the new features of the Q-series aim to improve networking and automation in the production process, as well as equipment availability. Updates and diagnostics can be run by the manufacturer using a simple remote VPN connection.

What’s more, operators are equipped with tools for assistance, troubleshooting and better visualisation. The modular design means the same housing can accommodate up to three power modules of 150 A each. So the power source can be composed of 150 A, 300 A or 450 A, allowing cutting performance to be adapted according to end user needs. Perfect for cutting material thicknesses from 0.5 to 120 mm.

Most suitable for use with cutting tables and for robot, pipe and profile cutting.

- Q-source: a power source with digitally controlled inverter power modules to regulate the current

- Q-torch: with improved quick disconnect, shorter design and automatic torch recognition by the power source

- Benefits of Q-Cut:

– Kjellberg Contour Cut and Silent Cut optimised even further

Contour Cut ensures an ideal oxygen mix ratio in the swirl gas. For straight cutting edges with minimum burr formation and oxide layer.

– 20% faster than HiFocus

– Small holes up to 0.75x plate thickness – e.g. an 8 mm hole in a 12 mm plate!

– Extended lifetime of Q consumables - Q-gas: fully automatic gas control through EtherCAT, based on pressure control

Q-gas O2 for steel (budget oriented and still the possibility to cut stainless steel/alu) - Marking: digital inverter technology ensures high-quality marking. From very fine marking without engraving to permanent marking with increased depth of the line – without any visible starting mark. Marking currents from 4 A up to max. 40 A.

Models:

- Q1500

- Q1500 Plus

- Q 3000

- Q 3000 Plus

- Q4500

The HiFocus neo series offers a high-end solution for cutting mild steel and stainless steel in the range between 0.5 mm and 160 mm. The various units available have a cutting current from 80 to 600 A. These cutting systems achieve highly precise cutting results, thanks to a refined design based on extensive R&D by Kjellberg Finsterwalde.

Set different cutting configurations and discover the results. The high cutting and marking speed considerably reduces cutting costs per metre and significantly boosts productivity .

Most suitable for use with cutting tables and for robot, pipe and profile cutting.

- Based on an inverter power module and suitable for heavier machines in conjunction with a thyristor power controller.

- PerCut 211m, PerCut 451m or PerCut 611m torches with Contour Cut technology cut small holes and contours with the highest precision. Minimum rework required. (Also available with Silent Cut from 2019.) PerCut torches and consumables boast an optimal lifetime thanks to the patented design and cooling principles. Choose from standard plate torches, special torches for robot applications or special machines such as pipe cutters and bevel heads.

- Also suitable for underwater plasma cutting (UWP cutting).

- Unique gas control based on flow rate measurement, for optimal gas mixture and constant flow. Especially handy when cutting stainless steel and aluminium using argon and hydrogen as plasma gas.

- Contour Cut ensures an ideal oxygen mix ratio in the swirl gas. For straight cutting edges with minimum burr formation and oxide layer.

- Marking: inverter technology ensures high-quality marking. From very fine marking without engraving to permanent marking with increased depth of the line. Marking currents from 4 A up to max. 40 A.

Models:

- Hi Focus 80i

- Hi Focus 161i

- Hi Focus 280i

- Hi Focus 360i

- Hi Focus 440i

- Hi Focus 600i

An efficient cutting result with minimal parameters and configuration. That’s what you can expect with the Smart Focus series. With just a few settings, these compact plasma cutting units achieve excellent results in the cutting range from 1 to 100 mm. The Smart Focus is also perfect for marking, underwater plasma cutting (UWP cutting) and bevel cutting.

Especially suitable for use with cutting tables.

The Smart Focus offers excellent value for money. Ideal for mild steel but also achieves great results on stainless steel and aluminium.

- Based on a thyristor power controller, allowing you to regulate the current between 10 A and 400 A thanks to a double, fully controlled thyristor bridge.

- PerCut 2000 and PerCut 4000 torches with Contour Cut technology cut small holes and contours with the highest precision – reducing rework to a minimum. (Also available with Silent Cut from 2019.) These PerCut torches and consumables boast an optimal lifetime thanks to the patented design and cooling principles.

- Also suitable for underwater plasma cutting (UWP cutting).

- The Smart Focus’s gas control is based on precise pressure control so that Contour Cut and Silent Cut give the best results.

- Fine marking with little engraving or deep permanent marking. Marking currents from 10 A up to max. 40 A.

Or choose your model:

- Smart Focus 130

- Smart Focus 170

- Smart Focus 200

- Smart Focus 300

- Smart Focus 400

Q, HiFocus and Smart Focus feature the very latest Kjellberg technologies. Contour Cut helps you cut small holes as well as straight outer contours with precision. Silent Cut is an extension to Contour Cut and significantly reduces noise by as much as 15 dB(A).

The CutFire plasma units are compact cutting tools, specifically for machine applications. They work with air plasma using an inverter for electronic power control, making them the ideal budget-friendly solution.

When combined with the Flash 101 torch, the CutFire achieves a high cutting speed and guarantees a long lifetime for your consumables.

Also suitable for bevel cutting (up to 30 degrees), piercing, marking and precision cutting.

- CutFire 100i is a powerful 100 A inverter-based power source with a gas-cooled Flash 101 torch. This delivers high-precision cutting and marking.

- Designed for machine applications and a 100% duty cycle.

- Cutting range 1 – 30 mm and cutting current up to 100 A.

Models:

- Cutfire 100i

The PA-S series is suitable for manual and mechanised cutting tasks, handling material thicknesses of 3 to 70 mm. These portable plasma cutting units are ideal for use in workshops, training centres and on construction sites.

The reliable and budget-friendly universal solution par excellence.

- Power sources with a conventional transformer and a diode bridge rectifier.

- The water-cooled torches PB-S45W xx and PB-S70W xx are available in several models and versions. Also for use with robots and special machines.

- PB-S44W swirl gas torch for better cutting quality.

- Suitable for manual cutting with a hand torch, mechanised use on cutting tables and even with a robot.

- Wide choice of gas boxes for air, oxygen and even argon/hydrogen mixtures.

Or choose your model:

- PA-S45W

- PA-S70W

Want to learn more about mechanical plasma cutting? Ask our team for advice. We will come up with a turnkey solution, tailored specifically to your business.