Kjellberg has become a byword for precision, efficiency and convenience over the past few decades. Discover the high-end technologies: Contour Cut, Contour Cut Speed, Silent Cut and PerfectBevel.

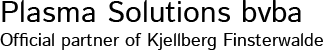

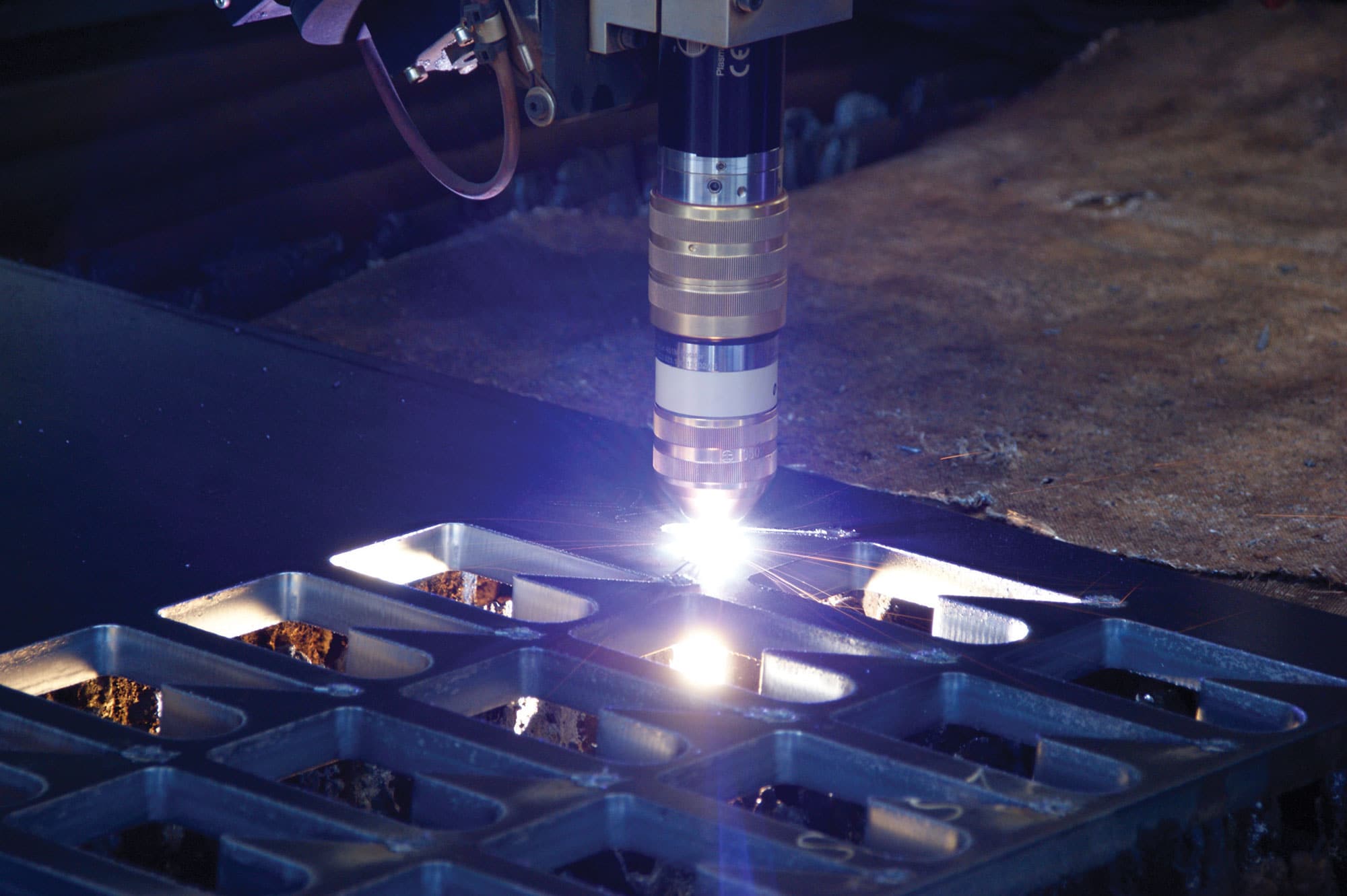

Contour Cut is a revolutionary and patented plasma cutting technology for precision cutting in mild steel. Until recently, cutting holes with the same diameter as the plate thickness was difficult. But now Contour Cut delivers outstanding results when cutting small holes, bolt holes and fine inner and outer contours.

Contour Cut Speed (CCS) also shifts things up a gear, cutting contours up to 50% faster.

- The Contour Cut technology is a combination of torch, consumables and type of lead-in and lead-out. Getting the timing, speed and movement of the cutting table or robot right is crucial.

- Uses oxygen in the swirl gas (or shielding gas) in the torch, so that the swirl gas actively plays its part in the cutting process. Ideal for cutting small holes, contours and straight-angled edges with the highest precision.

- Includes calculation tool for the machine manufacturer.

The high energy density and flow rate of the plasma gas during plasma cutting can result in noise of up to 100 dB(A). The higher frequencies especially can sometimes damage our hearing. That’s why Kjellberg Finsterwalde has developed the new Silent Cut technology, the latest addition to the patented Contour Cut technology. A unique combination of revolutionary plasma consumables and advanced cutting data.

Silent Cut reduces the noise level up to 15 dB(A) when plasma cutting steel with a material thickness between 4 and 30 mm and in the current range of 60 to 160 A. High frequencies are also considerably decreased. Reducing noise by 10 dB is perceived by the human ear as the equivalent of halving the sound level. And reducing noise by 15 dB significantly improves the health and safety of workers and operators. All while still guaranteeing the quality of cutting.

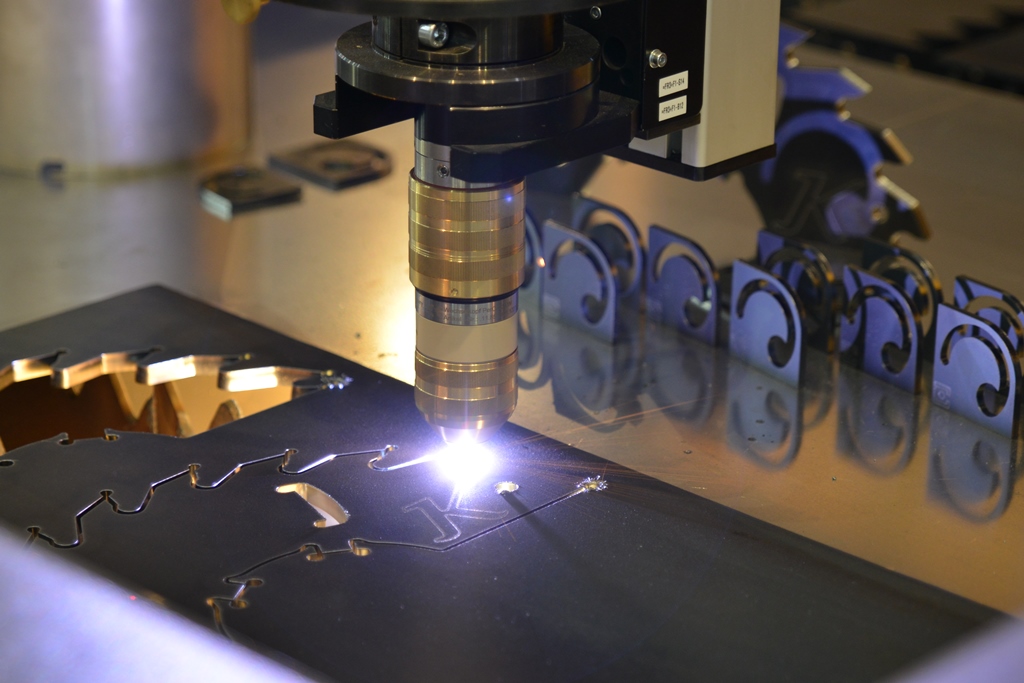

PerfectBevel is an extension to the standard database of cutting parameters. Weld seam preparation or bevel cutting takes up a significant amount of time in the cutting process. PerfectBevel provides an optimised database for bevel cutting metal plates with a material thickness of 5 to 30 mm.

The database also responds to the ever-increasing demands on quality, productivity, accuracy and reproducibility. Until a few years ago, weld seam preparation was rather a laborious and labour-intensive process, requiring a great deal of manual grinding. But modern plasma power sources and machines make this easier and faster.

Depending on the material thickness and type (e.g. mild steel, aluminium or stainless steel), the operator is given specific values and data from a specially developed database. The result is better accuracy and repeatability, less rework and better weld quality in the later stages of production.

Plasma Solutions also offers special plasma torches specifically developed for bevel cutting. The torch components stand out with their unique pointed and slim design for angles up to 50 degrees.

- Includes database of speeds and angle compensation values for common types of welds and based on the standard PerCut 451 (HiFocus) and PerCut 4000 (Smart Focus) torches

- The database is practical and compact, with the ideal parameters for current and thickness

- The PerfectBevel database contains values for V, X and K welds

Do you have a specific question about Kjellberg technologies? Or would you like to find out more about the benefits of Silent Cut, Contour Cut or PerfectBevel?