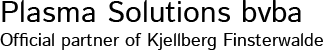

Kjellberg offers a range of welding technologies: InFocus high-power TIG, plasma-transferred arc (PTA) surfacing, and submerged arc welding, plus the latest ProFocus direct diode laser welding system.

InFocus welds various materials with extreme efficiency: mild steel, stainless steel, aluminium, copper, zinc, galvanised steel plates and profiles, and more. It is a high-performance alternative to conventional TIG welding and plasma welding. Simply adjust the parameters easily and quickly as appropriate.

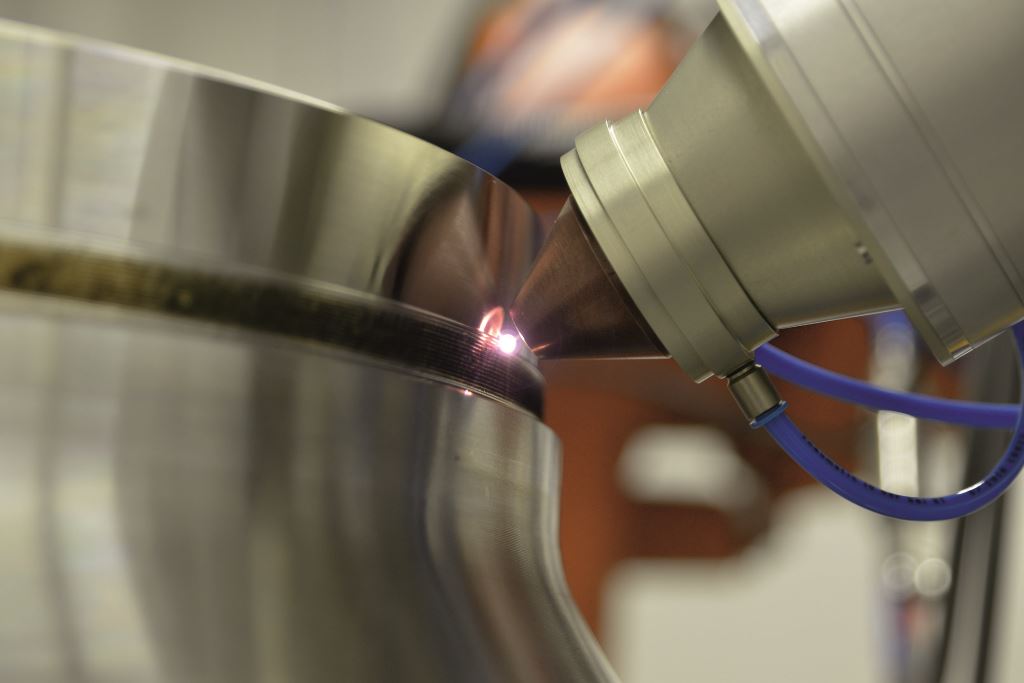

InFocus boasts a highly concentrated arc and excellent cooling up to the torch tip, guaranteeing superior quality and optimal process stability. Torch designs are available in different models and smaller versions. You can also use this tool to process less accessible workpieces with ease. The highly concentrated arc allows keyhole welding up to 8 mm thickness.

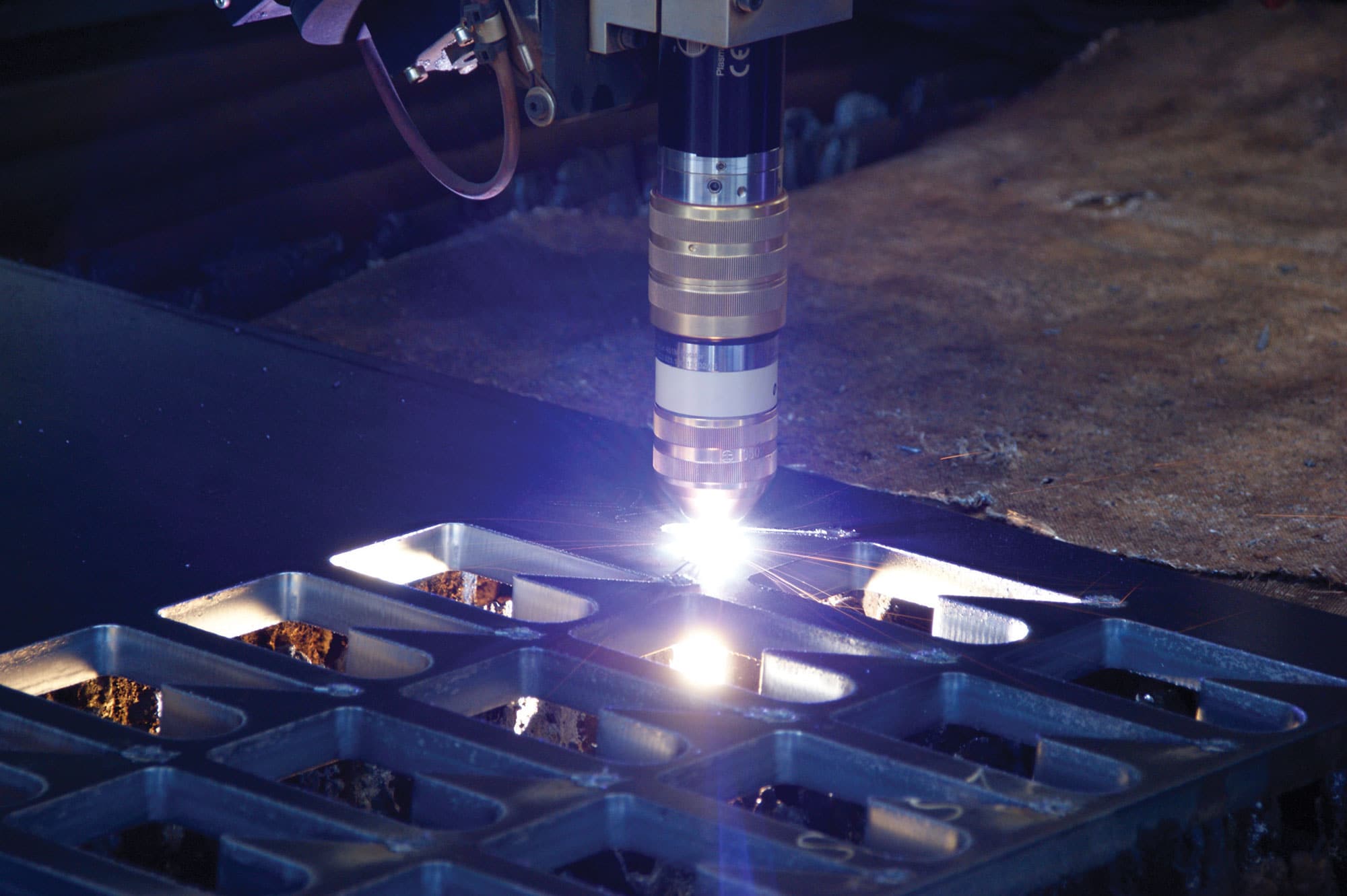

With the Kjellberg PSI 400 plasma welding inverter

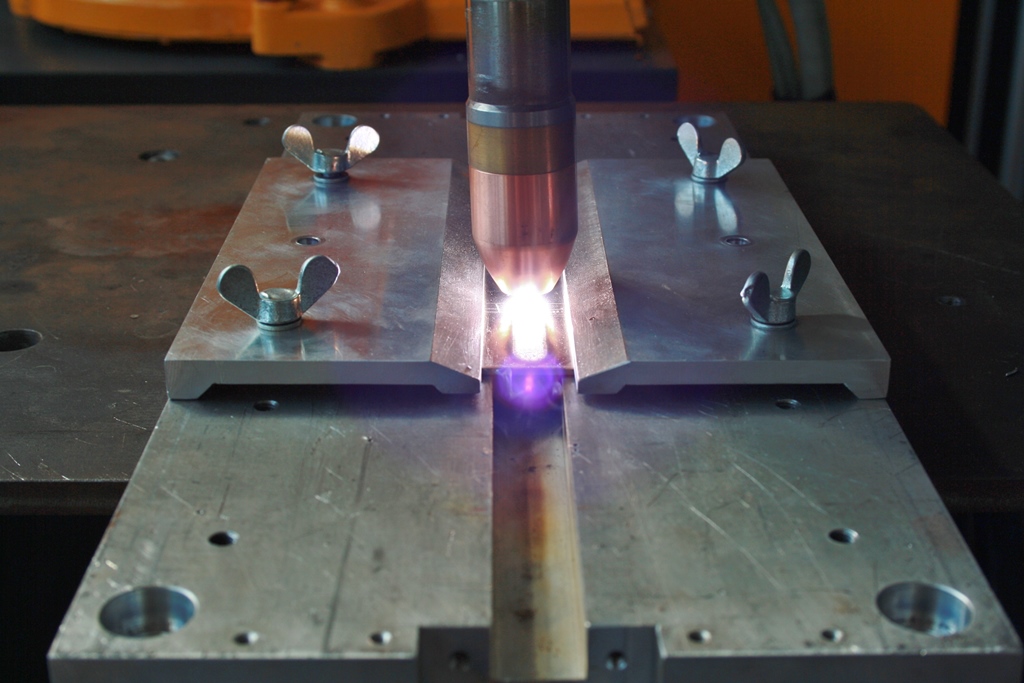

Plasma-transferred arc (PTA) welding is a thermal process for applying wear- and corrosion-resistant layers on the surfaces of metallic materials. The highly energetic plasma arc melts the surface of the base material, while the powder filler material is fed into the arc and also becomes molten. During solidification, a bond is formed between the base material and the filler.

The advantages of this process are a small heat-affected zone and a high deposition rate. It is also easier to produce the powder filler material than welding wires and rods.

With the PSI 400, you can also work in non-transferred arc mode, in which the plasma arc is used to apply an additional layer to the metal workpiece. The plasma arc causes the powder material to melt on the surface of the base material, without melting the base plate itself. The surfacing material is added to the plasma gas.

The PSI 400 is remarkably easy to use. Via a touch display, different user levels can be managed, offering several options for influencing the welding parameters and data management. Even the welding flux calibration is performed electronically. Specific flux data can be stored in the database. The PSI 400 delivers a maximum welding current of 400 A and a 100% duty cycle.

Submerged arc welding (SAW) uses a granular powder (flux) to protect the arc from external influences (e.g. oxidation). During welding, part of the powder melts on the surface of the weld, while another part is left behind on the product.

Kjellberg offers its own highly flexible solutions with SAW tractors and heads for machines – with single wire, parallel wire and multiple heads – as well as flux feed and recovery systems.

Models:

3D production or additive manufacturing has revolutionised design guidelines and manufacturing processes. The ProFocus coaxial diode laser offers flexibility and efficiency for powder or wire deposition welding. The coaxial structure guarantees multi-directional processing, even for semi-finished products.

Ultra-HDR cameras ensure reliable process monitoring. The ProFocus allows users to change the type of filler material within seconds. Different materials and material forms can be used on a single component in some cases.

Want to find out more about Kjellberg’s welding solutions?

We will be happy to get you in contact with the Kjellberg specialists.